Our standard big bags are particularly suitable for coarse, free-flowing materials and are available in basic dimensions between 70 cm and 125 cm with a freely selectable height. The big bags can be equipped with 1-point, 2-point, 4-point or 2-channel suspension.

Standard Big Bags

PRACTICAL BULK MATERIAL HANDLING

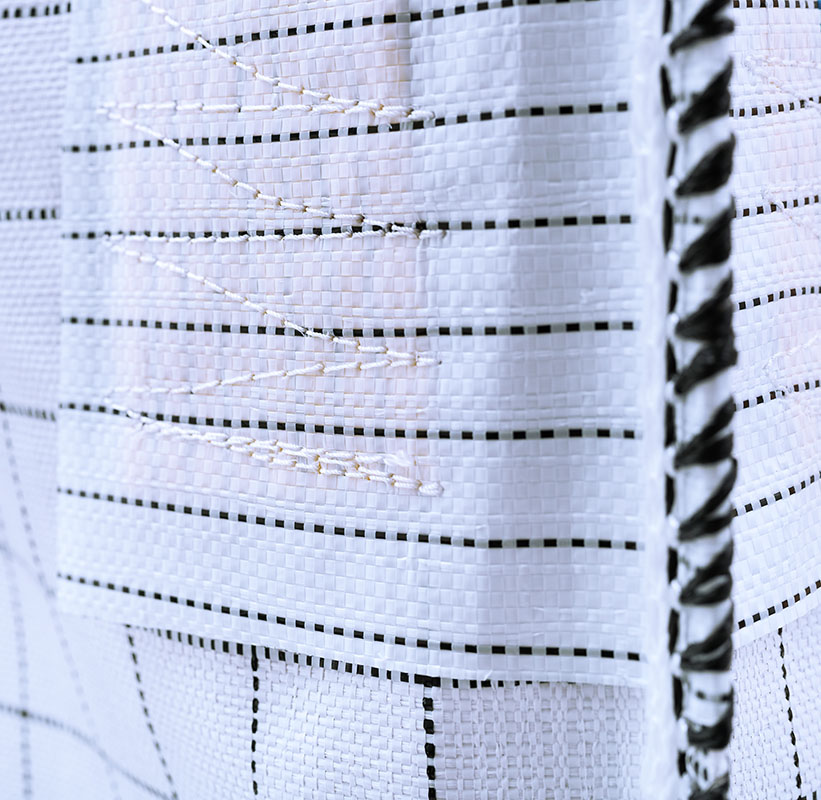

Dissipative Big Bags – ATEX

FOR SAFE EXPLOSION PROTECTION

Filling and emptying big bags can lead to electrostatic charging and cause explosions if the discharge is uncontrolled. To avoid this risk, we can supply you with big bags made of electrically conductive fabric. Carbon threads or multifilament yarns interspersed with stainless steel in the warp and weft safely conduct the charge to the earthing point. And it’s very easy to do: Simply attach an earthing clamp to one of the seams – done.

During filling, the upper area of your big bag is particularly at risk due to the separation that takes place and the resulting favoured accumulation of charge, which is why our belts are also electrically conductive. For filling processes with only a low electrostatic charge in an explosion-proof environment, we also offer big bags with an antistatic fabric finish, optionally with antistatic agents approved for foodstuffs.

Dangerous Big Bags

PROFESSIONAL TRANSPORT OF HAZARDOUS BULK MATERIALS

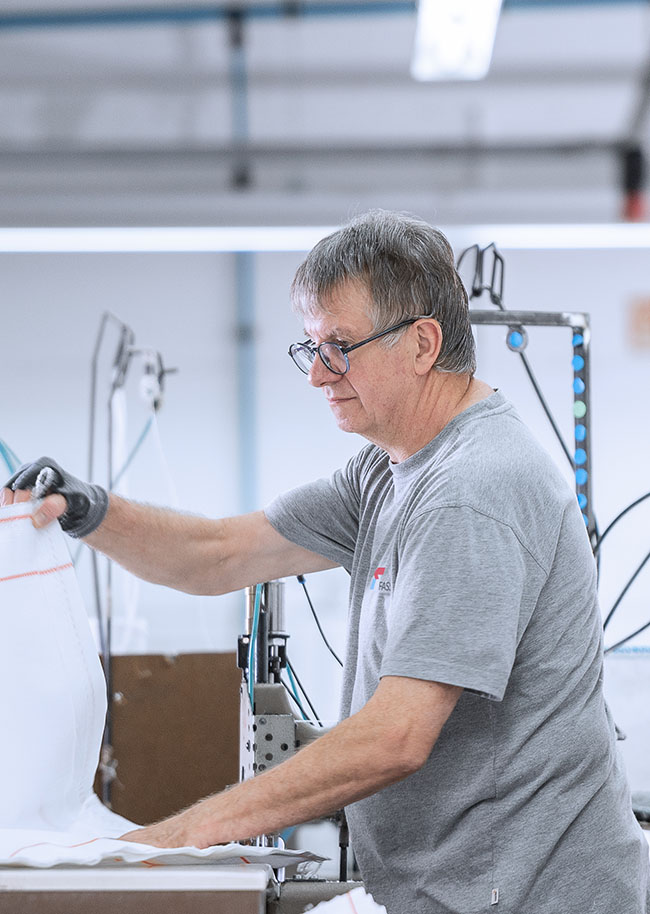

The transport of dangerous goods in public transport is regulated by the Dangerous Goods Ordinance for Road, Rail and Inland Waterways (GGVSEB). According to these regulations, containers in which dangerous goods are transported must undergo – and pass – prescribed test cycles. Easy for FASSE big bags.

Legislation stipulates that manufacturers of packaging for hazardous goods must be regularly audited by the Federal Institute for Materials Testing (BAM) or TÜV-like testing centres. FASSE INDUSTRIETEXTIEN GmbH has passed the monitoring of the criteria of incoming goods inspection, production process and employee qualification with flying colours, as well as a so-called destructive test of the packaging material.

Big bags for hazardous goods – also electrically conductive – are available from us in the following versions:

– 13H1 – FiBC made of uncoated fabric

– 13H2 – FiBC made from coated fabric

– 13H3 – FiBC made of uncoated fabric with inliner

– 13H4 – FiBC made of coated fabric with inliner

Food

APPROVED QUALITY FOR FOOD PROFESSIONAL TRANSPORT OF HAZARDOUS BULK MATERIALS

A decision in favour of packaging in the food sector is always a matter of trust. Big bags from FASSE fulfil the highest requirements thanks to their perfect production and constant controls. Our big bags and their hanging straps are made of tasteless and odourless pure polypropylene fabric. This prevents the packaging material from migrating onto the product. Bonded yarns are lint-free and oiled yarns are treated exclusively with BGA- and FDA-approved oils.

On request, your big bags can be supplied with inliners made of PE-LD, PE-HD, OPP/PA/PE or fixed aluminium composite films. The latter offer the best barrier properties against all kinds of influences. All our products for the food sector comply with the German Food and Commodities Act (LmBG) and fulfil the guidelines of the FDA (Food and Drug Administration). The recommendation III Polyethylene of the Federal Health Office is complied with as well as the requirements of the Code of Federal Regulations.

Customised solutions

WE MANUFACTURE YOUR PRODUCT IDEA

Talk to us if you are looking for solutions that are not standard designs or if you would like to realise your idea or your own existing design in a textile element. Whether container bags, special lifting or transport solutions or an innovation that enriches the market, we are always open to your requirements and wishes.

Customers of the packaging division benefit directly from synergy effects resulting from the close co-operation between our production lines. Depending on the requirements and application, we often also process materials for filter elements in our big bags – for filter big bags made of screen fabrics, multi-layer fabrics or membrane fabrics, which allow the goods in the packaging to react with a substance flowing through.